歡迎光臨4008云顶网站登录,促銷進行中!云顶集团游戏app支持全球發貨!

- 網站地圖

- 聯系云顶集团游戏app

- 關注微信

歡迎光臨4008云顶网站登录,促銷進行中!云顶集团游戏app支持全球發貨!

免費咨詢熱線

158-9680-3999Horizontal steam cooker is a kind of rotary drum dryer. Rotary drum dryer is rather old large-scale drying equipment, which uses cylinder rotation and air convection to transport and dry materials. The processing capacity is large, but the thermal efficiency is low when the hot air temperature is not high. Later, various types of improved structures appeared, one of which was the installation of tube bundles in the cylinder and using indirect heating of steam,the dryer improved the thermal efficiency greatly . It was first used in the soda industry in the 1930s and later in the polyester industry and the grain and oil industry.It shows great vitality in terms of low consumption and large flow of dry materials. In order to distinguish ordinary convection rotary dryer, this machine is called steam heating tube rotary dryer, English name: Rotary cylinder dryer with Steam tube, often called Rotary Dryer abroad.In China's soda ash industry, it is used to be called a steam roaster; in the oil industry, some are used for conditioning of oil seeds, commonly known as tube bundle conditioners, and some are used for steam cooking of oil seeds, commonly known as horizontal steam cooker.

我國油脂行業,第一臺大型的臥式蒸炒鍋1996年用于東海糧油榨油一廠,直徑3米,長18米,云顶国际代號:RD202,由美國安德森(Anderson)公司設計、國內制造,動力75KW,日處理菜籽量1500~2000噸。油脂行業用于大豆調質的大型旋轉干燥機由比利時迪斯美公司使用在冷脫皮工藝上,兩臺管束調質器,2004年安裝在廣州植之元5000TPD大豆壓榨線上。臥式蒸炒鍋與立式蒸炒鍋相比,處理量大、熱效率高、動力消耗低、操作簡單。2004年后,益海、中糧菜籽壓榨項目選用的都是臥式蒸炒鍋。由迪斯美公司承包的邦基在東莞的菜籽油廠,也是采用的臥式蒸炒鍋,直徑2.7米,長16米,迪斯美設計,國內制造。

In China's oil industry, the first large-scale horizontal steam cooker was used in the Eastocean grains and oils company Pressing Plant No.1 in 1996. It was 3 meters in diameter and 18 meters in length. The equipment code:RD202. It was designed by American company Anderson, made in China,with the power 75KW, and the daily processing capacity for rapeseed 1500 ~ 2000 tons. The large-scale rotary dryer used for soybean conditioning in the oil industry was used by the Belgian company Desmet for the cold peeling technology. Two sets of tube bundle conditioners were installed in the Guangzhou Zhizhiyuan 5000TPD soybean pressing line in 2004. Compared with vertical steam cooker, horizontal steam cooker has large processing capacity, high thermal efficiency, low power consumption and easy operation. After 2004, both Yihai Kerry and COFCO’s rapeseed pressing projects chose horizontal steam cooker. Bunge’s rapeseed oil factory in Dongguan , contracted by Desmet, also used horizontal steam cooker,with dia 2.7M and 16M length. It was designed by Desmet and made in China.

我國聚酯行業應用蒸汽管回轉筒干燥機技術始于70年代,由燕山石化引進德國產品,用在PTA和TA干燥上,由于國內聚酯行業的快速發展,截至1992年,國內大化工企業引進蒸汽管回轉筒干燥機近20套,促進了該技術在國內的推廣應用。在我國糧油行業,國內自主研發開始較晚,直到90年代末期,國內開發的蒸汽管回轉筒干燥機才開始裝備糧油加工企業,目前,國內已完全掌握了這種干燥機的設計、制造技術,最近在中糧廣東產業園菜籽壓榨項目上,直徑3.3米,長20米的臥式蒸炒鍋國產化云顶国际己經安裝在2000TPD菜籽生產線上。

The application of steam tube rotary drum dryer technology in China's polyester industry began in the 1970s. German products were introduced by Yanshan Petrochemical, used in PTA and TA drying, Due to the rapid development of the domestic polyester industry, until 1992, domestic large chemical companies introduced nearly 20 sets of steam tube rotary drum dryers. promote the popularization and application of this technology in China. In China's cereals and oils industry, domestic independent research and development started later, It was not until the late 1990s that the steam tube rotary drum dryer developed in China began to be equipped in cereals and oils processing enterprises. At present, China has fully mastered the design and manufacturing technology of such dryer. Recently, in the COFCO Guangdong Industrial Park rapeseed pressing project, domestic horizontal steam cooker with 3.3-meter diameter, 20-meter length has been installed in the 2000TPD rapeseed production line.

基本工作原理Basic working principle

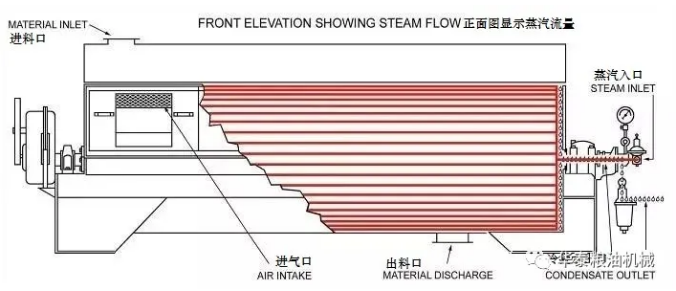

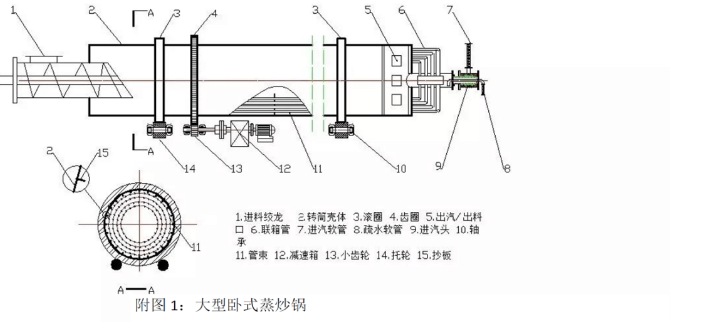

臥式蒸炒鍋的結構與回轉圓筒干燥器的結構基本相似,其主要區別在于回轉圓筒干燥器采用熱空氣為介質以熱對流方式對物料加熱干燥,臥式蒸炒鍋則利用轉筒內管束間接蒸汽以熱傳導方式對物料加熱。臥式蒸炒鍋的主要部分為一個與水平線略呈傾斜的旋轉圓筒,物料從轉筒較高的一端進入,與轉筒內固定加熱蒸汽管束接觸,隨著圓筒的旋轉,物料受自身重力和抄板的作用下流向較低的一端。臥式蒸炒鍋組成包括轉筒筒體、加熱裝置、支承裝置、傳動裝置等。

The structure of horizontal steam cooker is basically similar to that of rotary cylinder dryer. The main difference is that the rotary cylinder dryer uses hot air as the medium to heat and dry the materials in the way of heat convection, while the horizontal steam cooker uses the indirect steam of tube bundle in the rotary cylinder to heat the materials in the way of heat conduction. The main part of the horizontal steam cooker is a rotary cylinder slightly inclined to the horizontal line. The material enters from the higher end of the rotary cylinder and contacts with the fixed heating steam tube bundle in the rotary cylinder. With the rotation of the cylinder, the material flows to the lower end under the action of its own gravity and the plate. The horizontal steam cooker consists of a rotating barrel, a heating device, a supporting device, a driving device, etc.

主要特點Main features

與立式蒸炒鍋相比,臥式蒸炒鍋的最大優點是處理量大、節省能源、出料勻稱。以Ø3000×18米的臥式蒸炒鍋為例,配用電機功率75KW,用于軟化大豆,處理量為2500t/d;用于菜籽蒸炒,處理量為1200t/d。而相同處理量如采用Φ2100五層立式蒸炒鍋需配置20臺以上,每臺電機功率30KW,總裝機容量達600KW。臥式蒸炒鍋的傳熱面是筒體內部的管束,整個筒體除滾圈、齒圈外均包有保溫層,整臺云顶国际只需一只疏水器,蒸汽凝結水便于回收利用。而立式蒸炒鍋的傳熱面是鍋底加熱層板與加熱蒸汽外包層,每層均設有疏水器,立式蒸炒鍋的熱利用效率明顯低于臥式炒鍋。在立式蒸炒鍋內,四周物料運動線速度快,中央物料運動線速度慢,通常上層潤濕水分超過14%,鍋內即出現大的團塊;而臥式炒鍋潤濕水分可以達到18%以上,抄板不斷將物料翻動、拋散,物料無結團現象,因此,臥式蒸炒鍋更適合用于高水分蒸炒工藝。

Compared with the vertical steam cooker, the biggest advantage of the horizontal steaming cooker is its large processing capacity, energy saving, and uniform output. Take the horizontal steaming cooker of Ø3000 × 18 meters as an example, equipped with a motor whose power is 75KW, itf it is used to soften soybeans, its processing capacity is 2500t/d; if it is used for steam cooking of rapeseed , its processing capacity is 1200t/d. For the same processing capacity, if the Φ2100 five-layer vertical steaming cooker is used, more than 20 sets, the power of each motor is 30KW, and the total installed capacity is 600KW. The heat transfer surface of the horizontal steam cooker is the tube bundle inside the barrel. The entire barrel is covered with heat insulation layer except the rolling ring and gear ring. The whole equipment only needs one steam trap, and the steam condensate is easy to recycle. The heat transfer surface of the vertical steaming cooker is the bottom heating layer of the cooker and the outer layer of the heating steam. Each layer is equipped with a steam trap. The heat utilization efficiency of the vertical steaming cooker is significantly lower than horizontal cooker. In the vertical steaming cooker, the movement speed of the surrounding materials is fast, and the speed of the central material is slow. Generally, the moisture on upper layer is more than 14%, and large lumps appear in the cooker; while the moisture in the horizontal cooker can reach more than 18%, the stirring board continuously flips and throws the material, and the material has no agglomeration. Therefore, the horizontal steam cooker is more suitable for the high moisture steaming process.

常見問題Common Problem:

震動和噪音:由于云顶集团游戏app制作精度與現場安裝質量的原因,常會造成滾圈圓整度不夠,滾圈與齒圈不同心,引起云顶集团游戏app跳動和出現噪音。

Vibration and noise: Due to the accuracy of the equipment manufacture and the quality of on-site installation, the roundness of the roller ring is often insufficient, the roller ring and the gear ring are not concentric, causing the device to jump and noise.

進汽頭漏蒸汽:由于進汽管接頭是旋轉的,普遍采用的是球面密封。管球在接觸到高溫蒸汽和水后,很容易產生銹斑。旋轉接頭在轉動的情況下,密封接觸的地方是不會生銹的。長期的不轉動就會生銹,造成密封處有銹斑和銹坑。特別是一些工廠由于菜籽和大豆輪榨,蒸炒鍋有時停機長期不用,就會出現進汽頭的漏汽。

Inlet steam leakage: Since the inlet pipe joint is rotary, the spherical seal is commonly used. After contacting high-temperature steam and water, the tube bulb is easy to rust. When the rotary joint rotates, sealed and contact place will not rust. Long-term non-rotation will rust, resulting in rust spots and pits in the seal. Especially in some factories, due to the rapeseed and soybean take turns to be pressed, steam cooker are sometimes shut down for a long time, and there will be steam leakage at the steam inlet.

轉載自油脂工程師之家

Copyright © Copyright © 2020 河南省云顶国际有限公司 主營 精煉植物油|油脂云顶集团|油脂機械 版權所有